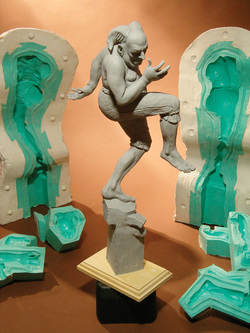

This picture is not one of my pieces, but it helps show the next stage that my elk sculpture will go through. In the image you can see the "green" of the rubber, usually a high quality silicone rubber that captures the detail of the clay. The the outside is either plastic or plaster to keep the shape. Now that the foundry has the original clay, they will apply liquid rubber with a catalyst, then allow it to set. After enough is applied and it is firm, the outer shell will be created. Once finished the mold becomes the important thing and the original is discarded, or kept by the artist for future reference or memories. The mold is then what liquid, melted wax is poured into. That wax is then used in the lost wax casting process that will eventually create a bronze sculpture, and in this case an elk bronze sculpture. For more info about the casting process, go here. I have confidence in the foundry to create a good mold and complete the piece. We should see it sometime in early Aug or late July.

RSS Feed

RSS Feed